This is the first post about designing and making a CNC for engraving PCBs. I would like to tell you about a journey that I went through to make this idea possible. I will tell you about how it has started, what issues I had and where it brought me.

To give you a little background I need to say that sometime ago I had bought a 3D printer. I didn’t expect to get that much into this, but I think it has pretty much gone the same way as for other people:

- printing ready models found on internet

- enhancing the printer itself to get better results

- tuning different parameters of the print to improve quality

- and finally - making your own desings

After making some simple functional prints I got this feeling that I need to go deeper and make something more complex. It was the time I got an idea to make a CNC which would be designed by definition to engrave PCBs so I no longer have to do thermal transfer.

The goal was to minimze the cost as much as I can and make it small (perfectly to fit on my desk). My first thought was that actually I might find a cheap CNC and just buy it. Well… looking at existing solutions was good also from inspiration point of view. I was considering below solutions:

I liked the The Ant PCB Maker but it was too expensive. So I have tried to design CNC 3018 but quickly found out that it was still too expensive because it was built with 2020 profiles. DIY Dremel CNC design and parts was not good enough because of the size.

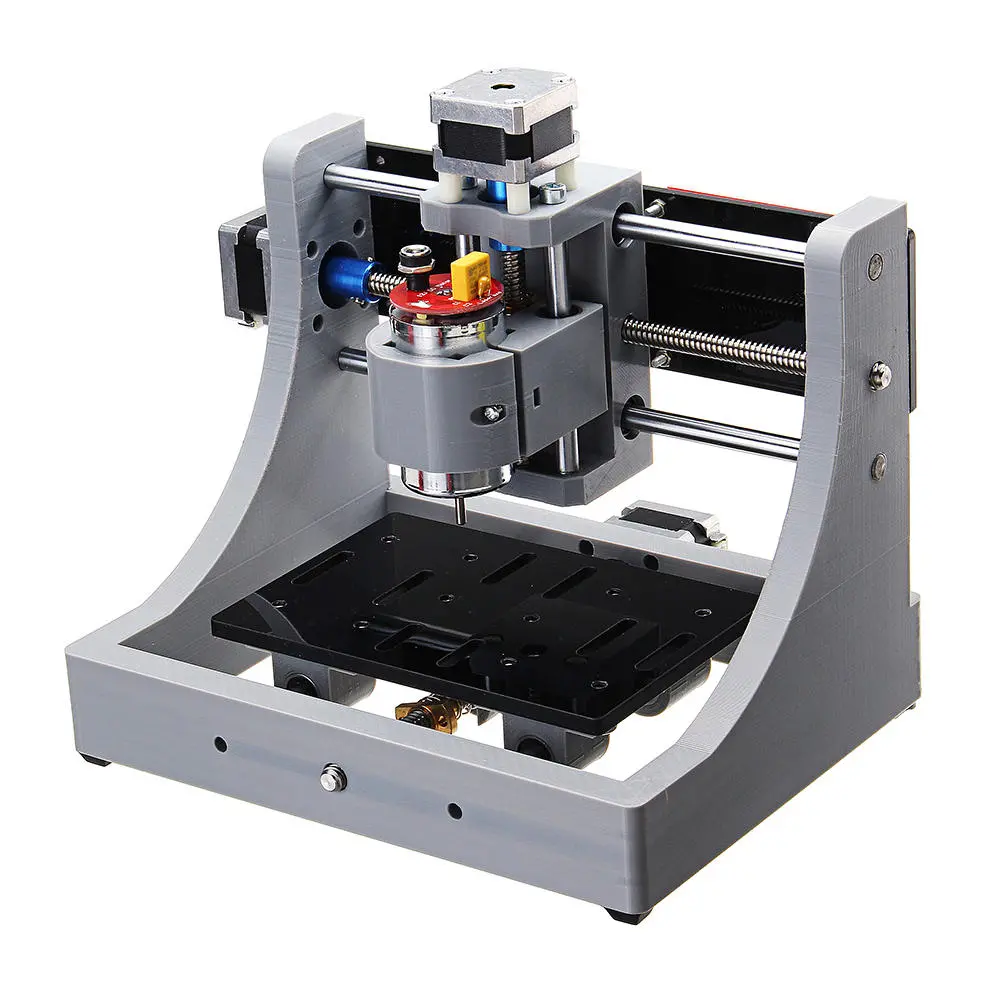

And then a break through happened for me. I have found 1208 3 Axis Mini Assembled CNC - machine which has the whole frame 3D printed! Until now I have not thought that such design might work. This was the perfect fit for me:

- it was small

- it was too expensive - so I didn’t want to but it

- making one by myself was more than twice cheaper - especially because I have already had some components that I needed

- it gave me possibility of improving my Fusion 360 design skills

1208 3 Axis Mini Assembled CNC, Source: www.banggood.com

1208 3 Axis Mini Assembled CNC, Source: www.banggood.com

This is how I have started to put my plan into practice. It was a big project for me - first of that size. I just let it take as much time as needed and do not rush. I just wanted to make it happen.

In next posts I will guide you through what I have actually done.